Quality Policy

- Dimensional Accuracy = 0.005 Mm.

- Surface Finish Within Ra 0.4,0.8

- Maintaining Excellent Gd &t Within 0.010 Mm

- Visually Shining And Defect Free Components.

- Continious Survelance Of Quality Parameters.

- Continius Improvement Of Process To Achieve Axcellent Quality.

- deburring Components With Proper Tools And Equipments.

- delevering The Components In Proper Packing And With Quality Documents.

Quality Control

Quality Control is Our Number one Priority for All CNC & VMC Precision Machining Products.

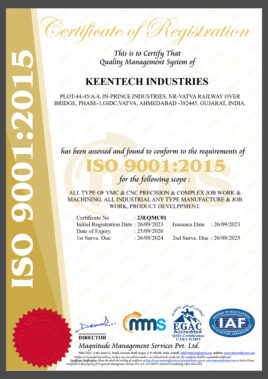

Custom Components & Assemblies, Inc. is a Keentech Industries CNC & VMC machine shop committed to an operating philosophy that exceeds our customer’s expectations for quality, safety, cost, delivery and value. Our customer’s needs are paramount and represent the highest priority within our business. Our obligations are to proactively identify and define each customer’s needs while adhering to all applicable standards and customer specific requirements. Calibration and maintenance protocols are an integral part of our maintenance program for all precision machining equipment. These protocols are designed to conform to the requirements of ISO 9001.2015.

Customer Communication

In accordance with our commitment to exceed our customer’s expectations, Custom Components & Assemblies, Inc. highlights effective customer communication as an essential element of delivering customer satisfaction.

Products and Services

The monitoring and measurement program for all precision machining products is defined in drawings and specifications, production routers, purchasing documents and in inspection and testing procedures.

Verification of Purchased Products

All purchased products are subjected to a visual inspection by the receiving inspector. Designated products are also subjected to a more detailed and technical quality control (QC) inspection.

In-Process Inspections

In-process inspections are in the form of first article inspections and operator inspections to ensure our quality and the on-time delivery of completed orders to our customers.

Final Acceptance Inspection

Finished CNC machining products are subjected to the final QC inspection. First, inspectors verify that all specified and in- process inspections have been completed. Then they perform the remaining inspections and tests necessary to complete the evidence of product conformity. Results of all inspections and tests are recorded and only products that pass the final inspection process are packaged and shipped.